Difference between revisions of "S7-SoftPLC:Classic View"

(Created page with "none This is the standard view of IBH''softec S7-SoftPLC''. Here the number of cycles, as well as the cycle times and jitter of the actual PLC p...") |

|||

| Line 97: | Line 97: | ||

'''Configure''' | '''Configure''' | ||

| − | Switches the user interface to [[ | + | Switches the user interface to [[S7-SoftPLC:Configuration View|configuration mode]]. |

After activating the button "Configure" the interface changes its display into the configuration view. Here drivers can be chosen and parameterised. Inputs, outputs, flags and data blocks can be observed and basic settings can be altered. | After activating the button "Configure" the interface changes its display into the configuration view. Here drivers can be chosen and parameterised. Inputs, outputs, flags and data blocks can be observed and basic settings can be altered. | ||

Latest revision as of 12:59, 19 December 2012

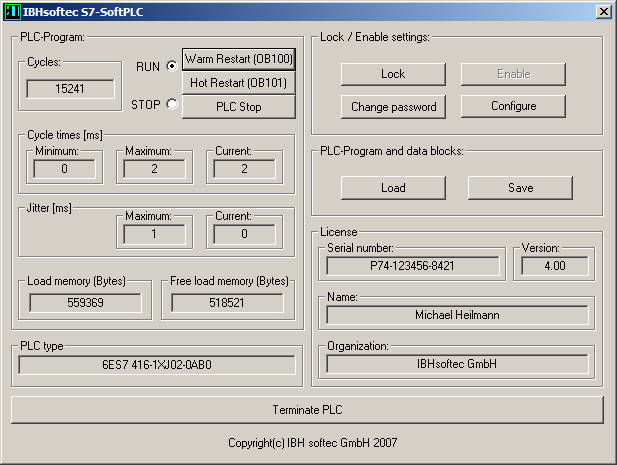

This is the standard view of IBHsoftec S7-SoftPLC. Here the number of cycles, as well as the cycle times and jitter of the actual PLC program can be seen. Available load memory, free load memory, PLC type, serial number, version, name and organization of the user are displayed as well. The classic view provides the possibility to restart, stop or close the S7-SoftPLC. Loading and saving the PLC-program into the installation folder, changing to the configuration view and locking the user interface to prevent unauthorised access is also possible.

Warm restart (OB100)

Activating the button "Warm restart", starts the PLC-program. First the organisation block OB 100 is processed. After this the cyclic program-processing starts with OB1.This is similar to the start-up of a hardware PLC after a voltage-return.

Hot restart (OB101)

Activating the button "Hot restart", starts the PLC-program. First the organisation block OB 101 is processed. After this the cyclic program-processing starts with OB1. This is similar to the start-up of a hardware PLC after manual switching from STOP to RUN.

PLC Stop

Activating the button "Stop", stops the cyclic program-processing. In the operating mode "STOP" the PLC-program is not processed. The status of the process images, flags, counters and timers, remain in the current state.

Terminate PLC

Activating the button "Terminate PLC", terminates the program. A restart of the S7-SoftPLC is possible at any time.

Cycles

The number of program-cycles is displayed here

Cycle times [ms]

The time a program-cycle takes place is monitored continuously by S7-SoftPLC.

The minimum, maximum and current cycle time of the current PLC-program are displayed. The resolution of a cycle time-measurement is one millisecond.

The cycle time of a PLC depends on the program structure. At the end of a cycle S7-SoftPLC saves the result of the cycle time-measurement. This is the time, that has past between two OB1 calls.

The time of a cycle (OB1 Cycle time) can be read out with the PLC-program.

| OB 1/LW6: | current cycle time in ms | (OB1_PREV_CYCLE) |

| OB 1/LW8: | maximum cycle time in ms | (OB1_MIN_CYCLE) |

| OB 1/LW10: | minimum cycle time in ms | (OB1_MAX_CYCLE) |

Jitter

Jitter is the variation in the cycle time of the S7-SoftPLC caused by the system itself.

If an output pulse from a timer OB (e.g. OB 10, every 10 ms) is measured, differences may be found. Jitter is the variation in time between the current measurement, relative to the previously measured time. You will see jitter with hardware and software PLC’s.

With S7-SoftPLC the jitter may be caused by programmed program-interrupts such as process alarms and also may occur due to hard disk access, network access, etc (system activities).

The Jitter of the S7-SoftPLC is constantly measured. The maximum jitter and the actual jitter is displayed.

Load memory

The load memory is the maximum size in bytes, that a PLC-programm may use. The free load memory is the size, that is still available and can be used by additional blocks. If too few free load memory is available, the PU can not transmit new blocks to S7-SoftPLC.

Lock settings

A manipulation of S7-SoftPLC by the user can be prevented by a password.

To lock S7-SoftPLC activate the button "Lock settings".

Now unauthorised access to the S7-SoftPLC is prevented.

NOTE: THE LOCKING HAS NO INFLUENCE ON THE PROGRAM SEQUENCE OF S7-SOFTPLC.

Enable settings

The locked S7-SoftPLC is enabled again.

To unlock S7-SoftPLC activate the button "Enable settings".

The S7-SoftPLC user interface can now be used to alter S7-SoftPLC configuration.

Change password

Changes the password.

After activating the button "Change password" a dialogue appears, where the old and two times the new password have to be entered to confirm the change.

The password has now been changed.

Configure

Switches the user interface to configuration mode.

After activating the button "Configure" the interface changes its display into the configuration view. Here drivers can be chosen and parameterised. Inputs, outputs, flags and data blocks can be observed and basic settings can be altered.

The S7-SoftPLC can now be configured.

Load

The PLC-program currently saved in the file "S7.BIN" in S7-SoftPLC's installation folder will be loaded into S7-SoftPLC.

Save

The PLC-program currently loaded in S7-SoftPLC will be saved as "S7.BIN" in the installation folder of S7-SoftPLC.

PLC type

Purchase order numbers compatible toS7-SoftPLC:

| 6ES7 315-1AF03-0AB0 V1.0 | S7-SoftSPS 315 without PROFIBUS® |

| 6ES7 315-2AG10-0AB0 V2.0 | S7-SoftSPS 315 with PROFIBUS® |

| 6ES7 315-2AG10-0AB0 V2.6 | S7-SoftSPS 315 with PROFIBUS® und TIA |

| 6ES7 315-2EH13-0AB0 V2.6 | S7-SoftSPS 315 with PROFIBUS® und TIA |

| 6ES7 416-1XJ02-0AB0 V1.0 | S7-SoftSPS 416 without PROFIBUS® |

| 6ES7 416-2XK02-0AB0 V1.1 | S7-SoftSPS 416 with PROFIBUS® |

| 6ES7 416-2XN05-0AB0 V5.1 | S7-SoftSPS 416 with PROFIBUS® und TIA |

| 6ES7 416-3ER05-0AB0 V5.1 | S7-SoftSPS 416 with PROFIBUS® und TIA |

Serial number

The serial number of the installed S7-SoftPLC

Version

Number of version fo the installed S7-SoftPLC

Name

Name of licence owner

Organisation

License owners organization/company name