IBHNet:IBH Link S5++

The IBH Link S5++ is a communication adaptor that permits to establish ethernet connections to the standard PU port of a SIMATIC® S5 PLC. Under normal circumstances the IBH Link S5++ obtains its power supply from the PU port of the CPU. If the PLC does not deliver power, the 24V can be supplied externally. The outer pin is 0V (GND), the inner pin is +24V.

Besides PU functions with S5 for Windows® also S7-HMI devices can read and write variables from the PLC. The following protocols are supported:

- PU communication with S5 for Windows®

- IBHsoftec OPC Server for Visualization (HMI) PC

- Fetch / Write via TCP/IP

- S7-TCP/IP (RFC1006) Variable services for current S7-HMI Panels

Upon delivery the IBH Link S5++ has the IP address 192.168.1.13. If no DHCP server is available in the network, it falls back to this address. In order to find and configure the device, the IP address of the configuration PC may be changed to match the IBH Link S5++ via the Control Panel.

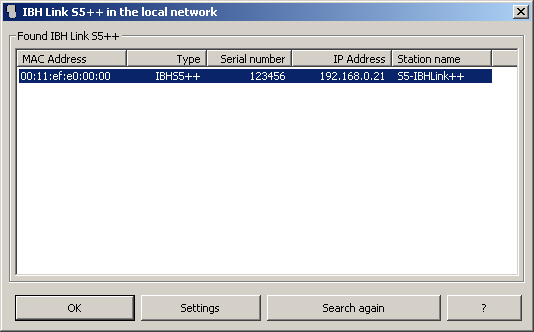

To set the address, the program "S5IBHLink.exe" needs to be started. The following screen appears:

- OK - Exits the configuration

- Settings - Opens the configuration dialog for the selected link

- Search again - Searches for devices in the local network again

- ? - Opens the help

The IP address can be set either static or can be obtained from a DHCP server. If set to DHCP, a DHCP server should be available in the network.

To use PU functions with S5 for Windows®, the desired port number can be set. By default this is 10010.

For Visualization (HMI) systems, that support the protocol Fetch/Write S5 via TCP/IP, the desired port can be set as well. The Fetch/Write requests will be decoded and be forwarded to the AS511 port of the PLC.

For Visualization (HMI) systems, that support the S7 protocol RFC1006 via TCP/IP, the port is always 102. The MPI® telegrams sent via RFC1006 will be decoded and be forwarded to the AS511 port of the PLC.

Save permanently - Saves the settings in the IBH Link S5++flash memory. Following dialog appears:

After successful restart the device is ready. Further configuration is not required.

Parallel services:

All services can be used in parallel. But it should be considered, that the AS511 port of the S5 only works with 9600 baud and the communication load will be shared by all services. This fact may require higher timeout settings for the connected devices.

Operation with S7 HMI devices:

For the operation with S7 HMI devices the following settings need to be made:

- IP address of the PLC = IP address of the IBH Link S5++

- Rack number of the PLC = 0

- Slot number of the PLC = 2

- MPI® address of the PLC = 2

- The checkbox "Cyclic operation" (WinCC Flexible / ProTool) must be OFF. For WinCC "Use cyclic read service of PLC" must be OFF.

- In the message settings of the project the checkboxes for "S7-Diagnostic messages" (Text and Number) must be OFF. Also the "SIMOTION diagnostic messages" must be OFF, since these services are not available on a S5.

Some thoughts about the S7 HMI projects:

Since a S7 communication is by nature much faster than a S5 communication may ever be, this fact should be considered. When creating a project for a S7 HMI device that talks to a S5, some project guidelines can be found below.

- Timers respectively Counters may change during a read/write cycle. For this reason they are deactivated. If they are addressed by the HMI device, a "PLC address Error" will be returned. If Timers and Counters are required, they must be managed via a data block.

- Values can be read and written from the input and output process image, as well as flags and the content of datablocks.

- It is recommended to optimize the variable areas already during creation the project, in order to permit the fastest possible data exchange with the S5 PLC.

- If there are many single variables from different areas of the PLC in one screen of the project, many single requests need to be sent to the S5, in this case the integrated optimization cannot do it's work. This takes time. For this reason the refresh rate of a variable should be reduced to permit the PLC to answer the requests within the time frame configured in the project.

- If optimization can fully work, refresh rates from 200-300ms are realistic. If there is no optimization possible, reading may take a few seconds. An average refresh rate of a second should be a good point to start.

- However, in some cases it will make sense to combine all variables within one screen to an array. With only one read/write cycle blocks of data can be exchanged optimized with the S5. This saves time and better refresh rates can be gained.

- DB addresses are word oriented in S5. The DW0 in a S5 is equivalent to the DBW0 of a S7. The DW5 of a S5 is equivalent to the DBW10 of a S7. All other addresses within DBs follow this logic.

S5 S7 DL 0 DBB 0 DR 0 DBB 1 DL 1 DBB 2 DR 1 DBB 3 DL 2 DBB 4 DR 2 DBB 5 oder DW 0 DBW 0 DW 1 DBW 2 DW 1 DBW 4 ... ...

Attention: During an active block status with the programming unit, all active connections running in parallel will be stalled. They will continue, as soon as the block status is exited from the programming unit. The reason is, that the PU needs to reserve the PLCs programming port exclusively in order to execute the block status function. If HMI applications are running in parallel to the PU, the user has to take this into consideration.