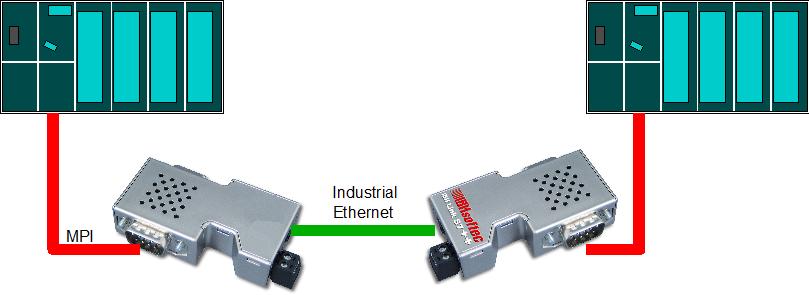

IBHNet:Unprojected PLC-PLC communication

Starting with firmware version 2.142, it is possible with the IBH Link S7++ and the IBH Link S7++ HS to establish connections via the IBH Link from a PLC to multiple other PLCs. Via MPI® normally only unprojected connections are possible to other PLCs. Projected connections are only possible via Ethernet or PROFIBUS.

To set up a communication between PLCs, it is essential that the PLCs in question support the S7 basic communication features. The presence of the following SFCs will tell us:

- SFC67 - "X_GET"

- SFC68 - "X_PUT"

- SFC69 - "X_ABORT"

To establish a connection to another PLC, the first call of "X_PUT" must send a structure with the connection information. Every further call of "X_PUT" respectively "X_GET" exchanges data over this connection. If you want to communicate with another PLC, the structure with the connection data has to be sent again with the new connection information. The current connection will be ended and the new connection will be established.

Definition of the structure:

| Adress | Name | Type | Value | Comment |

|---|---|---|---|---|

| 0.0 | bIpAddr | ARRAY[0..3] of BYTE |

C0 A8 00 31 | Hexadecimal representation of the IP Address. In the sample 192.168.0.49 = C0A80031 |

| 4.0 | bMpiAddr | BYTE | B#16#2 | The MPI® address of the partner PLC. |

| 5.0 | bRack | BYTE | B#16#0 | The rack number of the partner PLC [0..7]. |

| 6.0 | bSlot | BYTE | B#16#2 | The slot number of the partner PLC [0..31]. |

| 7.0 | bSubSlot | BYTE | B#16#0 | Reserved. |

The various possibilities for unprojected communications between PLCs are shown in a PDF file. The files explaining the communication types can be found in the installation folder. Sample projects showing the communication over function blocks written in SCL can also be found there.

| Attention: With unprojected connections via MPI® only 1 (One) connection to a partner PLC is possible at a time. This is, because the requests from the PLC must be sent to the MPI® address of the IBH Link S7++ or IBH Link S7++ HS. Parallel connections are not possible because of the lack of an ID. If parallel connections shall be used, projected S7 connections via the IBH Link S7++ or IBH Link S7++ HS need to be used. |