Difference between revisions of "IBHLink S5++:SIMATIC® S5 WinCC flexible"

| (4 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

| − | It is possible to realize a connection from a WinCC flexible Runtime/Panel to a | + | It is possible to realize a connection from a WinCC flexible Runtime/Panel to a SIMATIC S5 station over ethernet using an [http://www.ibhsoftec.com/IBH-Link-S5-PP-Eng IBHLink S5++] as gateway. |

==Example== | ==Example== | ||

| − | In the following example a configuration with ''' | + | In the following example a configuration with '''WinCC flexible''' is shown. |

| − | The HMI station is connected to the IBHLink S5++ via an Ethernet connection. The IBHLink S5++ itself is connected to a | + | The HMI station is connected to the IBHLink S5++ via an Ethernet connection. The IBHLink S5++ itself is connected to a SIMATIC S5 station on the AS511 port. Communication parameters were configured by the IBHNet configuration tool. |

The following addresses were chosen in the example: | The following addresses were chosen in the example: | ||

| Line 27: | Line 27: | ||

| Slot number of the PLC || 2 | | Slot number of the PLC || 2 | ||

|- | |- | ||

| − | | | + | | MPI address of the PLC || 2 |

|} | |} | ||

Configuration: | Configuration: | ||

| Line 35: | Line 35: | ||

[[Image:WinCCFlex_Connections.png|766px]] | [[Image:WinCCFlex_Connections.png|766px]] | ||

| + | '''Some thoughts about the S7 HMI projects:''' | ||

| + | |||

| + | Since a S7 communication is by nature much faster than a S5 communication may ever be, this fact should be considered. When creating a project for a S7 HMI device that talks to a S5, some project guidelines can be found below. | ||

| + | * Timers respectively Counters may change during a read/write cycle. For this reason they are deactivated. If they are addressed by the HMI device, a "PLC address Error" will be returned. If Timers and Counters are required, they must be managed via a data block. | ||

| + | * Values can be read and written from the input and output process image, as well as flags and the content of datablocks. | ||

| + | * It is recommended to optimize the variable areas already during creation the project, in order to permit the fastest possible data exchange with the S5 PLC. | ||

| + | * If there are many single variables from different areas of the PLC in one screen of the project, many single requests need to be sent to the S5, in this case the integrated optimization cannot do it's work. This takes time. For this reason the refresh rate of a variable should be reduced to permit the PLC to answer the requests within the time frame configured in the project. | ||

| + | * If optimization can fully work, refresh rates from 200-300ms are realistic. If there is no optimization possible, reading may take a few seconds. An average refresh rate of a second should be a good point to start. | ||

| + | * However, in some cases it will make sense to combine all variables within one screen to an array. With only one read/write cycle blocks of data can be exchanged optimized with the S5. This saves time and better refresh rates can be gained. | ||

| + | * DB addresses are word oriented in S5. The DW0 in a S5 is equivalent to the DBW0 of a S7. The DW5 of a S5 is equivalent to the DBW10 of a S7. All other addresses within DBs follow this logic. | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| Line 66: | Line 76: | ||

The configuration of the connection is now completed and you can continue with defining your Tags. | The configuration of the connection is now completed and you can continue with defining your Tags. | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Attention: | ||

| + | |- | ||

| + | | During an active block status with the programming unit, all active connections running in parallel will be stalled. They will continue, as soon as the block status is exited from the programming unit. The reason is, that the PU needs to reserve the PLCs programming port exclusively in order to execute the block status function. If HMI applications are running in parallel to the PU, the user has to take this into consideration. | ||

| + | |} | ||

Latest revision as of 10:45, 19 September 2013

It is possible to realize a connection from a WinCC flexible Runtime/Panel to a SIMATIC S5 station over ethernet using an IBHLink S5++ as gateway.

Example

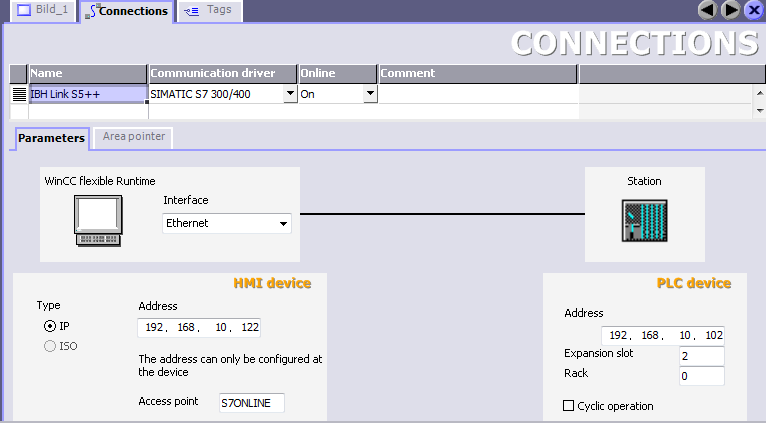

In the following example a configuration with WinCC flexible is shown. The HMI station is connected to the IBHLink S5++ via an Ethernet connection. The IBHLink S5++ itself is connected to a SIMATIC S5 station on the AS511 port. Communication parameters were configured by the IBHNet configuration tool.

The following addresses were chosen in the example:

IP addresses:

| Station | Address |

|---|---|

| HMI station | 192.168.10.122 |

| IBHLink S5++ | 192.168.10.102 |

Operation with S7 HMI devices: For the operation with S7 HMI devices the following settings need to be made:

| IP address of the PLC | IP address of the IBH Link S5++ |

| Rack number of the PLC | 0 |

| Slot number of the PLC | 2 |

| MPI address of the PLC | 2 |

Configuration:

The ethernet communication driver for S7 300/400 must be selected in WinCC flexible, since only this driver allows the selection of an extension slot on the PLC side.

Some thoughts about the S7 HMI projects:

Since a S7 communication is by nature much faster than a S5 communication may ever be, this fact should be considered. When creating a project for a S7 HMI device that talks to a S5, some project guidelines can be found below.

- Timers respectively Counters may change during a read/write cycle. For this reason they are deactivated. If they are addressed by the HMI device, a "PLC address Error" will be returned. If Timers and Counters are required, they must be managed via a data block.

- Values can be read and written from the input and output process image, as well as flags and the content of datablocks.

- It is recommended to optimize the variable areas already during creation the project, in order to permit the fastest possible data exchange with the S5 PLC.

- If there are many single variables from different areas of the PLC in one screen of the project, many single requests need to be sent to the S5, in this case the integrated optimization cannot do it's work. This takes time. For this reason the refresh rate of a variable should be reduced to permit the PLC to answer the requests within the time frame configured in the project.

- If optimization can fully work, refresh rates from 200-300ms are realistic. If there is no optimization possible, reading may take a few seconds. An average refresh rate of a second should be a good point to start.

- However, in some cases it will make sense to combine all variables within one screen to an array. With only one read/write cycle blocks of data can be exchanged optimized with the S5. This saves time and better refresh rates can be gained.

- DB addresses are word oriented in S5. The DW0 in a S5 is equivalent to the DBW0 of a S7. The DW5 of a S5 is equivalent to the DBW10 of a S7. All other addresses within DBs follow this logic.

| S5 | S7 |

|---|---|

| DL 0 | DBB 0 |

| DR 0 | DBB 1 |

| DL 1 | DBB 2 |

| DR 1 | DBB 3 |

| DL 2 | DBB 4 |

| DR 2 | DBB 5 |

or

| DW 0 | DBW 0 |

| DW 1 | DBW 2 |

| DW 2 | DBW 4 |

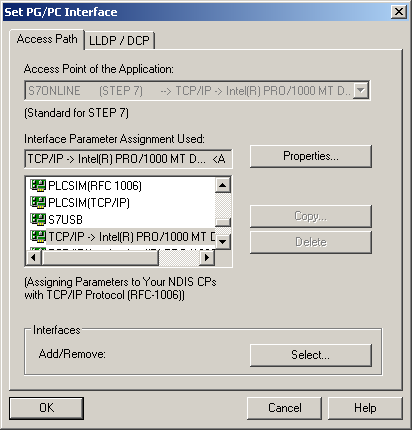

If you are using the WinCC flexible Runtime, please check that in the settings of the PG/PC Interface the correct driver TCP/IP for the Access Point S7ONLINE is chosen.

The configuration of the connection is now completed and you can continue with defining your Tags.

| Attention: |

|---|

| During an active block status with the programming unit, all active connections running in parallel will be stalled. They will continue, as soon as the block status is exited from the programming unit. The reason is, that the PU needs to reserve the PLCs programming port exclusively in order to execute the block status function. If HMI applications are running in parallel to the PU, the user has to take this into consideration. |