Difference between revisions of "OPCServer:Variables from LOGO! RCE"

(→Communication) |

|||

| Line 5: | Line 5: | ||

==Communication== | ==Communication== | ||

| − | The communication with the LOGO! uses the ethernet protocol of the S7- | + | The communication with the LOGO! uses the ethernet protocol of the S7-200. Following variables can be read/written from/to the LOGO!: |

* Order number | * Order number | ||

| Line 14: | Line 14: | ||

Reading the operational state of the PLC does not interfere with the communication, but does not deliver useable results. | Reading the operational state of the PLC does not interfere with the communication, but does not deliver useable results. | ||

| − | |||

== Settings of the LOGO! over it's display == | == Settings of the LOGO! over it's display == | ||

Latest revision as of 14:23, 19 September 2013

Contents

IBH OPC Server with Siemens LOGO! (RCE versions)

The RCE versions of the Siemens LOGO! are equipped with an ethernet port and support S7 connections over ethernet. This permits to integrate the LOGO! into more comlex environments, as per example connecting it to an HMI. Often, HMI applications use OPC as connection to the PLC. Below the configuration for exchanging data with the LOGO! and the IBH OPC Server is described.

Communication

The communication with the LOGO! uses the ethernet protocol of the S7-200. Following variables can be read/written from/to the LOGO!:

- Order number

- Inputs

- Outputs

- Flags

- DB1, it's configuration is made with the LOGO! Soft Comfort software

Reading the operational state of the PLC does not interfere with the communication, but does not deliver useable results.

Settings of the LOGO! over it's display

First, the LOGO! must be accessible over the ethernet network. Then the IP addres can be set with the LOGO! Soft Comfort software. If neccessary, the IP address of the PC needs to be changed, to have LOGO! and PC in the same subnet. The current address of the LOGO! can be looked up in the display.

- "ESC" opens the settings.

- Move down to "Network..".

- "OK" - "IP address" is shown. "OK" The current address is displayed.

Settings with the LOGO!Soft Comfort software

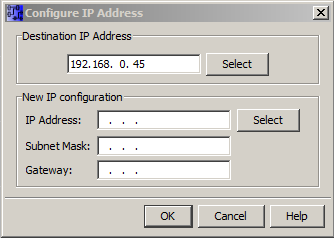

In the LOGO!Soft Comfort software the IP address of the PLC must be set. This is made with "Tools - Transfer - Configure Network Address...".

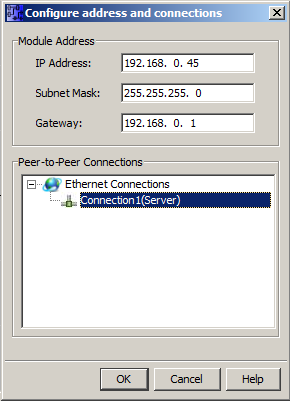

Then the LOGO! must be configured to accept connections from a HMI device. Over "Tools - Ethernet Connections..." a connection can be added or modified.

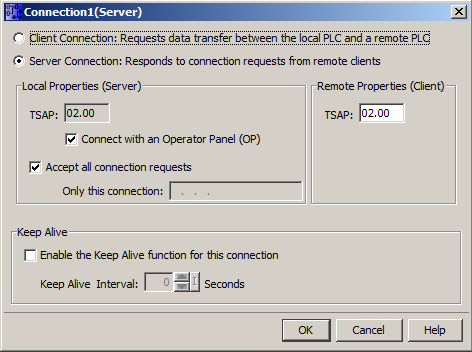

A doubleclick on the connection opens a configuration dialog.

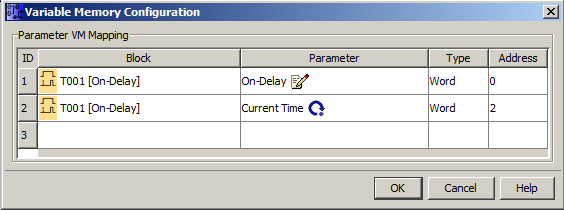

A Server Connection must be chosen. The TSAP settings (lokal and remote) are '02.00'. To read variables from the DB1, it must be created. With "Tools - Parameter VM Mapping..." the elements from the PLC programm can be arranged in the DB1.

It may happen, that the LOGO! Soft Comfort software must be restarted, before changes in the connection settings will be transferred to the PLC.

Settings within the IBH OPC Server

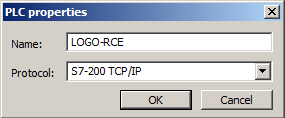

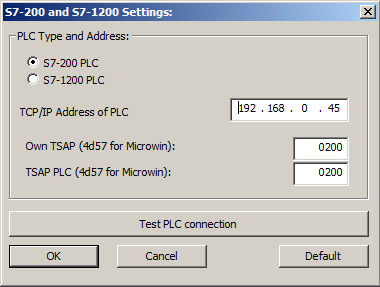

In the IBH OPC Server the PLC type 'S7-200 TCP/IP' must be selected.

In the TSAP settings (lokal and remote) '0200' must be entered.

Possible variables are inputs, outputs, flags, the DB1 and the order number. Any OPC client may now communicate with the IBH OPC Server and read/write data from/to a LOGO! with ethernet port.